Pro Tip

Key Features

- Full 500' Spool

- Unique Braided Construction

- Wide Expandability

- Quick & Easy Installation

- Wide Operating Temperature Range

- Chemical Degradation Resistant

- UV Radiation Resistant

- Abrasion Resistant

- Cuts Easily & Cleanly with Hot Knife

Description

Versatile Braided Cable Bundling & Protection Solution - 1/2" - Snake - Full 500' Spool

|  |

|  |

Expandable Sleeving with a Wide Range of Colors & Sizes

The FLEXO PET (PT) grade is used in electronics, automotive, marine and industrial wire harnessing applications where cost efficiency and durability are critical.

The unique braided construction and wide expandability allows quick and easy installation over large connectors and long runs. PT can be found in applications ranging from small office/home office to high tech wire and cable harnesses.

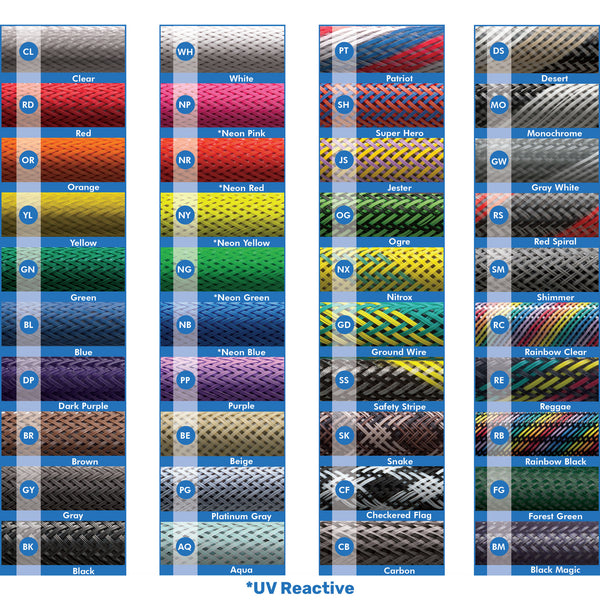

The wide range of available colors and sizes allows easy and systematic color coding in complex wiring and cabling schemes.

PET is braided from 10 mil polyethylene terepthalate (PET) monofilament yarns. The material has a wide operating temperature range, is resistant to chemical degradation, UV radiation, and abrasion. The sleeving cuts easily and cleanly with a hot knife and once installed, will beautify and protect any wire, hose or cable application.

What is Braided Sleeving?

Flexo PET (PT) is used in electronics, automotive, marine and industrial wire harnessing and management applications where cost efficiency and application durability are important. The unique braided construction allows expandability up to 150% or more for quick and easy installation over large connectors and long installation runs. PT is braided from 10 mil PolyEthylene Terepthalate (PET) monofilament yarns. The material has a wide operating temperature range, resists chemical degradation, UV damage and abrasion.

Why Use Braided Sleeving?

We believe sleeving is the best of all worlds when it's time to deal with harnesses, snakes and bundles, and we want to convince you that some type of sleeving will be the perfect balance of economy, ease of use and long term usability for your applications. Unlike other products designed for cable management, expandable sleeving is quick and economical to install on applications of virtually any length. In addition, the reduced weight and volume of sleeving is negligible to the overall diameter and weight of the application. The visual appeal of braided sleeving is an important factor as well. Many companies and individuals the world over use Techflex brand braided sleeving for their wires, tubes, cords, and more. For professional applications, home installations, and even arts and crafts projects, Techflex braided sleeving is your best solution!

Features:

- Provides Profesional Look on Products

- Resists Common Chemicals, Solvents, and UV Damage

- Economical and Easy to Install

- Cut and Abrasion Resistant

Specifications:

- Nominal Size: 1/2"

- Product Part #: PTN0.50

- Expansion Range Min.: 1/4"

- Expansion Range Max.: 3/4"

- Spool Put-Ups Bulk: 500'

- Spool Put-Ups Shop: 100'

- Avail. Colors: 33

- Lbs/100': 0.770

- Physical Properties

- Monofilament Thickness (ASTM D-204): .010

- Flammability Rating: UL-94

- Recommended Cutting: Hot Knife

- Colors: 28

- Wall Thickness: .025

- Tensile Strength - Yarn (ASTM D-2265) lbs.: 7.5

- Abrasion Resistance: Medium

- Specific Gravity: 1.38

- Moisture Absorption % (ASTM D-570): .1 - .2

- Hard Vacuum Data (ASTM E-595 at 10-5 torr)

- TML: .19

- CVCM: .00

- WVR: .16

- Smoke D-Max (ASTM E-662): 56

- Outgassing: Medium

- Oxygen Index (ASTM D-2863): 21

- Operating Temperatures:

- Minimum Continuous: -94°F/-70°C

- Maximum Continuous (MIL-I-23053): 257°F/125°C

- Melt (ASTM D-2117): 482°F/250°C

- Other Information

- Halogen Free: Yes

- RoHS: Yes

- SVHC: None

- UL/CSA: Yes

- Chemical Resistance

- 1=No Effect 2=Little Effect 3=Affected 4=More Affected 5=Severely Affected

- Aromatic Solvents: 2

- Alipahtic Solvents: 1

- Chlorinated Solvents: 3

- Weak Bases: 1

- Strong Bases: 2

- Salt Water (O-S-1926): 1

- Hydraulic Fluid (MIL-H-5606): 1

- Lubricating Oil (MIL-A-8243): 1

- De-Icing Fluid (MIL-A-8243): 1

- Strong Acids: 3

- Strong Oxidants: 2

- Esters/Ketones: 1

- UV Light: 1

- Petroleum: 1

- Fungus (ASTM G-21): 1

- Salts: 1

- Manufacturer: Techflex

- MPN: PTN0.50SK-500

- Model Number: Flexo PET 1/2" Snake - 500' Spool