Key Features

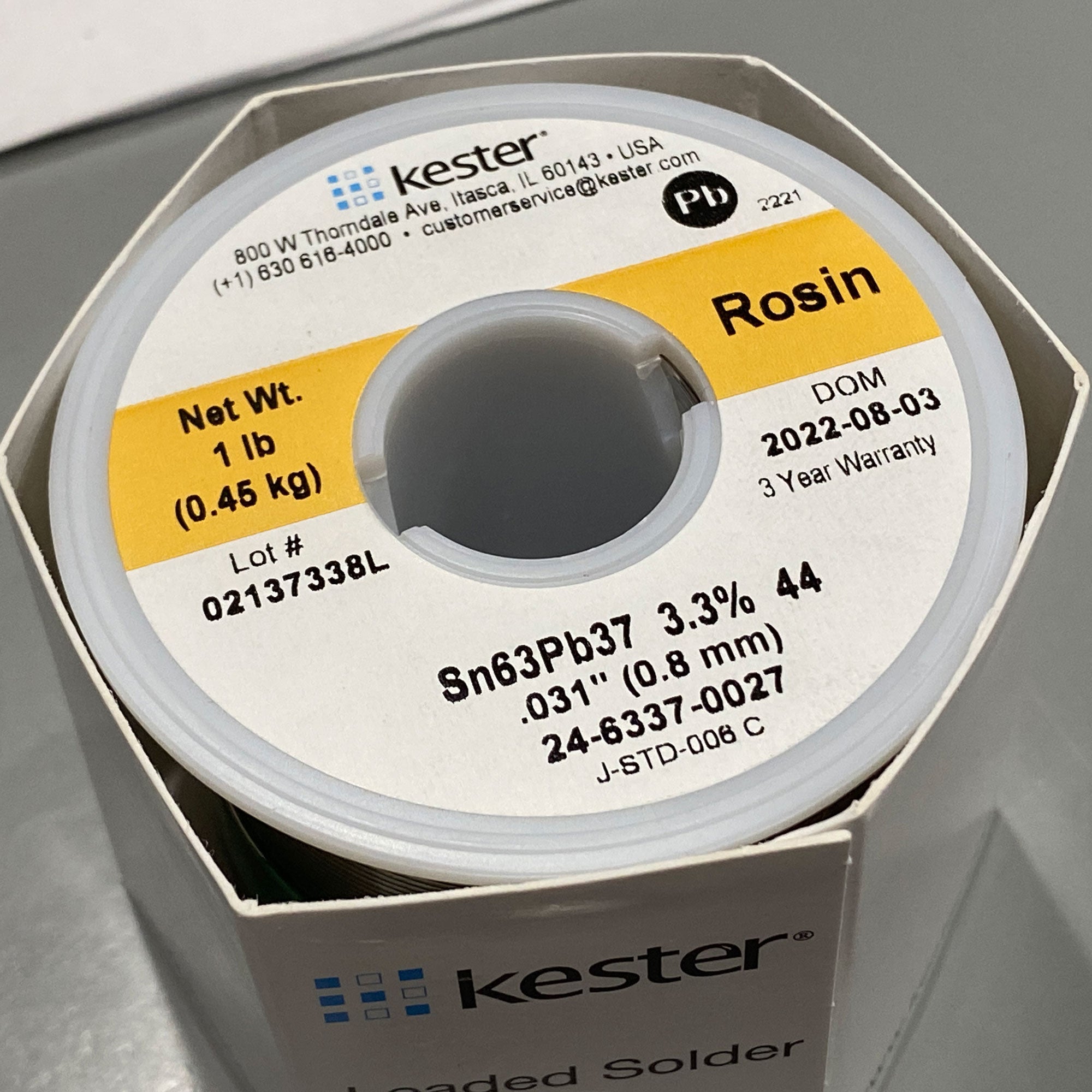

- Core Size 66

- 0.031" Diameter

- 63/37 Alloy

- Instant Wetting Action

- Non-Conductive Flux

Description

44 Flux-Cored Wire - Activated Rosin Cored Wire for Lead-Free and Leaded Alloys

Kester "44" rosin core solder is designed for electronic and electrical work. It uses a fast acting, instant wetting, non-corrosive, and non-conductive flux for faster soldering and a strong, long lasting bond.

Kester 44 Flux-Cored Wire is an activated rosin formula for use in flux-cored solder wire. 44 has virtually dominated the field of activated rosin core solders for well over five decades. An outstanding performance feature of this flux is the "instant-action" wetting behavior. The high mobility and fast-spreading action of this flux results in more reliable production line soldering. Under IPC J-STD-004, 44 is classified as ROM1. Despite the increased activity and soldering performance, 44 passes both 85°C/85% RH and 40°C/90% RH SIR test methods.

Performance Characteristics:

- High activity RA formulation

- Passes both 85 °C/85% RH and 40°C/90% RH IPC SIR testing

- Excellent solderability to a wide range of metallizations

- Industry standard RA cored wire for decades

- Classified as ROM1 per J-STD-004

RoHS Compliance

Kester does not determine any applicable Restriction of Hazardous Substances (RoHS) exemptions for our lead containing products at the user level. (Applies only if this core flux is combined with a lead-free alloy.)

Reliability Properties

Copper Mirror Corrosion: Moderate

Tested to J-STD-004, IPC-TM-650, Method 2.3.32

Corrosion Test: Moderate

Tested to J-STD-004, IPC-TM-650, Method 2.6.15

Silver Chromate: Fail

Tested to J-STD-004, IPC-TM-650, Method 2.6.33

Chloride and Bromides: 0.44%

Tested to J-STD-004, IPC-TM-650, Method 2.6.35

Fluorides by Spot Test: Pass

Tested to J-STD-004, IPC-TM-650, Method 2.6.35.1

Surface Insulation Resistance (SIR) 40 °C/90% RH, IPC (typical): Pass

Tested to J-STD-004B, IPC-TM-650, Method 2.6.3.7

Surface Insulation Resistance(SIR), IPC (typical): Pass

Tested to J-STD-004, IPC-TM-650, Method 2.6.3.3

Test Conditions: 85 °C, 85% RH, 7 days, 100V

| Blank | 44 | |

| Day 1 | 7.46*109 Ω | 2.2*108 Ω |

| Day 4 | 4.9*109 Ω | 2.88*109 Ω |

| Day 7 | 7.7*109 Ω | 7.14*109 Ω |

Availability

44 is available in a wide variety of alloys, wire diameters, flux percentages and roll sizes in both leaded and lead-free alloys. The most common alloys are Sn63Pb37 and Sn60Pb40. Please refer to https://www.kester.com for more information.

Note: Core size 50, 58 and 66 = 1.1%, 2.2% and 3.3% flux core, respectively.

Process Considerations

Solder iron tip temperatures are most commonly between 315 to 343 °C (600 to 650 °F) for leaded alloys and 371 to 400 °C (700 to 750 °F) for lead-free alloys. Heat both the land area and component lead to be soldered with the iron tip prior to applying the solder wire to land area or component lead. Do not apply the wire directly to the soldering iron tip; doing so will shorten the life of the soldering tip.

Additional liquid flux should only be used as a last resort. Any flux applied to the solder location should be kept to the area of the connection being reworked. If needed, Kester 186 or Kester NF372-TB may be used as a compatible liquid fluxes to aid in reworking soldered joints. Kester 186 and Kester NF372-TB are also available in Flux-Pens for optimum board cleanliness.

Cleaning

44 possesses excellent fluxing ability; the flux residues are non-corrosive, non-conductive and do not require removal for most applications under normal conditions of use. IPA will not clean the residues off the surface of the circuit board after the soldering process. If removal is required, a saponifier or cleaning agent specifically designed to clean a no-clean flux is required to clean the residues. Please contact Kester Technical Support for further information.

Storage, Handling and Shelf Life

Storage must be in a dry, non-corrosive environment between 10 to 40 °C (50 to 104 °F). The surface may lose its shine and appear a dull shade of grey. This is a surface phenomenon and is not detrimental to product functionality. Flux-cored solder wire has a shelf life determined by the alloy used in the wire. For alloys containing more than 70% lead, the shelf life is 2 years from the date of manufacture. Other alloys have a shelf life of 3 years from the date of manufacture.

Health and Safety

This product, during handling or use, may be hazardous to your health or the environment. Read the Safety Data Sheet and warning label before using this product. Safety Data Sheets are available at this link.

Features:

- High activity RA formulation

- Passes both 85°C/85% RH and 40°C/90% RH IPC SIR testing

- RoHS Compliance

- Excellent solderability to a wide range of metalizations

- Industry standard RA cored wire for decades

- Classified as ROM1 per J-STD-004

CALIFORNIA PROP 65 WARNING: This product can expose you to chemicals including lead which is known to the State of California to cause cancer and birth defects or other reproductive harm. For more information go to www.P65Warnings.ca.gov.

- Manufacturer: Kester

- MPN: 24-6337-0027

- Model Number: 24-6337-0027

- UPC: 768249062660